Si 466® has innovation at its core!

Challenges facing products are constantly changing. Today, the challenges facing the environment are increasing. For the tire industry, sustainable and environmentally friendly production have never been more important. The production of Green Tires using Si 466® is free from the emission of ethanol coming from a silane. This solution comes 50 years after Evonik filed the first patent for Si 69®. As experts in silanes, we continuously develop new high-performing products.

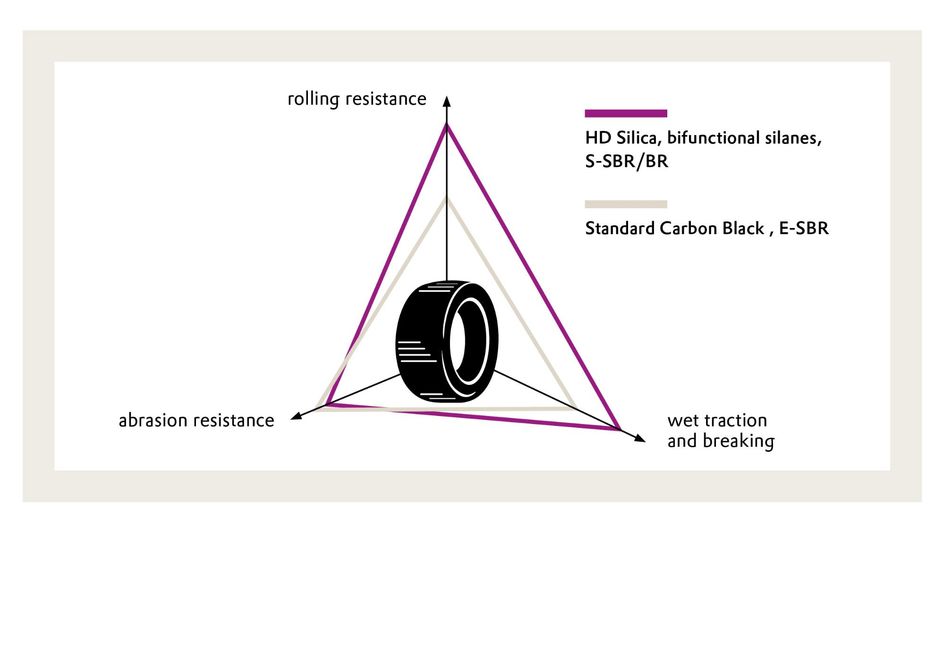

The introduction of Green Tires in the 1990s improved the technology and performance of passenger cars. Previously, carbon black had been used as a filler, but the performance was limited as a compromise had to be made between the key performance indicators in the so-called magic triangle. The development of the Silica/Silane-system in Green Tires marked a significant improvement in car tire performance compared with conventional carbonblack-filled tires. Today, the story of the Silica/Silane-system is being driven forward with Si 466®. With Si 466®, the production of tires is VOC free, which improves the sustainability of tire manufacturing.

The success story of the Green Tire in the 1990s was down to Si 69®—a product first developed in the early 1970s. 50 years after the patent for Si 69® was filed, the same innovation and reliability continues with Si 466®. Our researchers do not only focus on performance but also extensively test with regards to the processability and production of tires. This focus on all aspects of the tire has led to continuous development, which has led to innovative solution such as Si 466®. Si 466® offers the same tire performance as Si 266® and other well established silane products but without any emission of volatile organic compounds (VOCs) during production. As consumers, industries, and governments look to reduce their impact on the environment, Evonik is providing solutions. In all industries, the impact of products on the environment needs to be lower. By eliminating the emission of VOCs from tire production, the tire industry can become more sustainable.

The Green Tire improves sustainability and driver’s safety

Active fillers are essential for the performance and durability of rubber. Carbon black was replaced by silica in the 1990s, which led to the introduction of the Green Tire. This development in the technology of tires heralded a significant performance improvement. The magic triangle with its three key performance indicators—rolling resistance, abrasion resistance, and wet grip—is used to assess the overall performance. Compared to carbon black, the Silica/Silane-system improved the performance of rolling resistance and wet grip without compromising on abrasion resistance. But this improvement required a change in the technology of the tires. Polar silica and non-polar rubber do not efficiently mix so an additional component is required. Researchers at Evonik discovered that organosilane act as an outstanding bonding material between silica and rubber and the Silica/Silane-system was introduced:

Since the introduction of the Silica/Silane-system, Evonik has continued to make advances in the technology behind tires by addressing the challenges faced by the industry. Si 466® is a bifunctional silane, which consists of three structural units; the silica-reactive unit, the organic spacer, and the polymer-reactive unit. During mixing, the silica reactive unit reacts with the silanol group of the filler and during vulcanization, the polymer reactive unit reacts with rubber. The alkoxy group of the silane forms covalent bonds with silica. Normally, ethoxysilane is used so that during the mixing and vulcanization of the tire, ethanol is emitted. There is a desire in the industry to reduce VOCs. Si 466® is a VOC-free coupling agent. In Si 466®, alkoxy groups are replaced by a non-volatile leaving group so no VOCs are emitted during mixing and vulcanization. The performance of VOC-free silane was tested and compared against a standard Green Tire and its performance was matched.

Si 466®: Sustainable solution without any compromise in the magic triangle

Si 466® has been on the market for some time. It was first developed ten years ago and is currently used in shoe soles. As sustainability becomes a priority for regulators, governments, and consumers, the tire industry needs to respond and provide environmentally friendly and sustainable solutions. With Evonik’s experience and knowledge in silanes, Si 466® offers a sustainable solution without any compromise in the magic triangle.

When it comes to tires, low rolling resistance, high abrasion resistance, and good wet grip need to be considered. Previously with carbon black and conventional tires, drivers needed to decide between rolling resistance or wet grip. With Green Tires and the silica–silane system, a compromise isn’t required. The dual functionality of silanes enables covalent bonding between the inorganic substrates and organic substrates. The silane tail bonds with silica and its organic head bonds with the rubber to create a crosslink between filler and of polymer. The chemistry behind the Green Tire improves the rolling resistance of tires, which keeps money in the driver’s pocket. Meanwhile, a high wet grip keeps them safe even in extreme weather conditions.

Si 69®: 50 years of innovation

Si 69® was the product that kicked off this change. It is a well known polysulfidic bifunctional silane in the industry and is used in car tire tread as an additive. 50 years after it enter the market, it remains an innovative product. It reacts with the silanol groups of the silica fillers and during vulcanization forms covalent bonds with the polymer. Si 69® is used in various fields in which the silane–silica system is applied and optimum technical properties are required. In the history of tires, the success of the Silica/Silane-system is unmatched. This success was only possible with sulfur silanes. Sulfur silanes are the additive required to ensure efficient and thorough mixing and chemical bonding of the hydrophilic silica and hydrophobic rubber. Conventional tires using carbon black as a filler have a lower wet grip and lower rolling resistance. With the Silica/Silane-system, fuel economy and wet grip are improved without any change in abrasion behavior. Since the use of Si 69® in the Silica/Silane-system, Evonik has continued to improve the performance of these high-tech composite materials. . The innovation in silane products at Evonik has led to Green Tire being the tire of choice on passenger vehicles today. As the industry looks to step up to the challenge of reducing and eliminating VOCs, the solution has already been provided with Si 466®.

Si466®: Significantly reduced carbon footprint due to the achieved gasoline savings

This improvement hasn’t gone unnoticed by consumers either. Tires featuring the Silica/Silane-system can cut fuel consumption by up to 8 % owing to their reduced rolling resistance. Additionally, an improved wet grip means that braking distance is significantly reduced. Drivers do not only see an impact on their wallets, but their safety is improved, too. Generally, tires based on Si 466® become more sustainability and this innovative product leads to a significantly reduced carbon footprint due to the achieved gasoline savings. The performance difference between conventional and Green Tires has been further highlighted by regulators. Since 2012, the EU tire label has provided more transparency for drivers. Tires are classified from A (best) to G (worst) based on the tire’s rolling resistance, wet grip, and noise levels. In Europe, the Silica/Silane-system in car tires has become the norm. From 2010 to 2015, the market share of Green Tires in total sales volume increased from 10 % to 30 % globally. The performance of Green Tires continues to be enhanced as researchers at Evonik continue to develop improved organosilanes. Researchers at Evonik don’t just consider car tires as rubber products—they are high-tech composite materials, which require constant innovation to ensure reliability and performance.

Evonik Silanes: Global footprint for local proximity

Evonik is a global player. Our magic triangle is innovation, availability, and reliability and there is no compromise. With production sites of rubber across three continents and further technical sites spread across the globe, Evonik is in a unique position to guarantee local availability and technical support. From developing Si 69® in the 1970s, the Green Tire in the 1990s, to now, Evonik continues to stay ahead of the curve by investing in technology. The challenges facing customers today already have a solution. The development of products is orientated to the client with custom manufacturing available. Research and development capabilities are followed up with technical services to ensure superior and constant product quality. Investment in testing centers for performance and processing is continually occurring so products sold by Evonik are tested to the highest standards.

Innovation was key 50 years ago and it will not change in the next 50 years. Constant focus on innovation and the future, while maintaining availability and reliability has meant Evonik can continue serving its customers with innovative and quality products. Materials with outstanding performances only remain that way if innovation is a key part of the business model. With Si 69® 50 years ago to Si 466® now, we have consistently provided our customers with the products they need to tackle the challenges they face.