Si 466® EXT has innovation at its core!

Challenges facing products are constantly changing. Today, the challenges facing the environment are increasing. For the tire industry, sustainable and environmentally friendly production have never been more important. The production of green tires using Si 466® EXT is free from the emission of ethanol coming from a silane. This solution comes 50 years after Evonik filed the first patent for Si 69®.

Conventional tires use carbon black as a filler. To replace carbon black, an additive is required to thoroughly mix non-polar rubber and polar silica. In the 1990s, the green tire was launched based on a Silica/Silane-system. Evonik, with its expertise in silanes, provided the solution for the original green tire. Since then, the Silica/Silane system has been continuously developed to improve processing and production. Today, as the tire industry looks to become more sustainable, volatile organic compound (VOC) free solutions are sought.

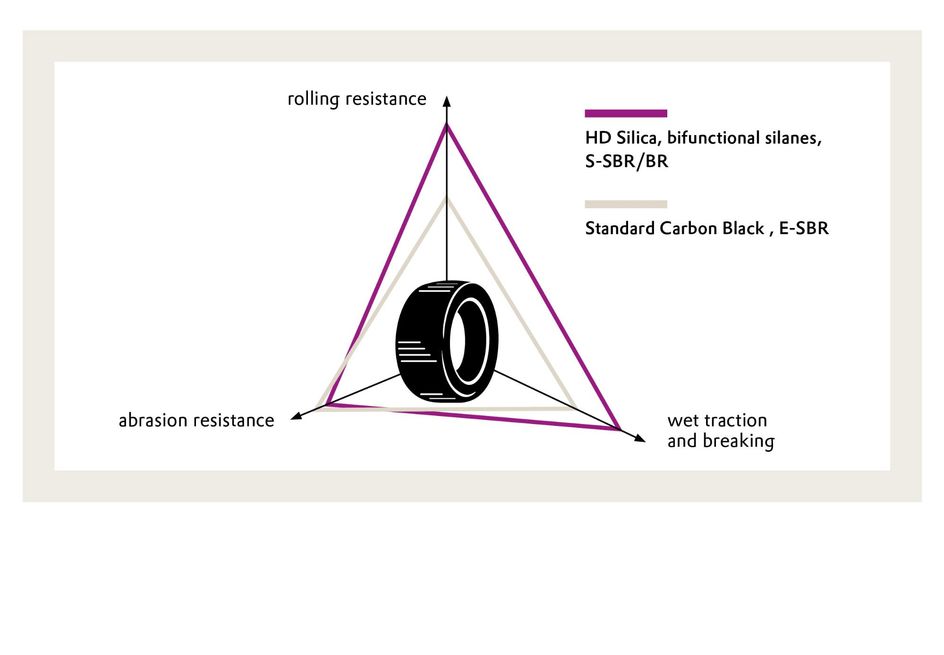

Si 466® EXT is a VOC-free coupling agent. During mixing and vulcanization, the hydroxyl groups on the surface of silica react with a silane to form covalent bonds. When an ethoxyfunctionalized silane is used, it reacts with the hydroxyl groups, and ethanol is released. Unlike other silanes, the coupling agent does not contain ethoxysilane, which means, ethanol or other VOCs are not emitted during processing. The performance of Si 466® EXT in tire compounds was tested against a standard green tire and its performance was matched. Important tire properties like wet grip, rolling resistance and abrasion resistance on a comparable level were achieved. The introduction of the Silica/Silane-system in the 90s improved the technology and performance of tires. Silica instead of carbon black changed the chemical reactions in the rubber mixture. The inorganic functional part of the silane covalently bonds with polar silica and the organic part of the silane forms a covalent bond with non-polar rubber. This change in the chemistry led to better-performing tires. The key performance indicators wet grip, rolling resistance, and abrasion resistance form the magic triangle, which the tire industry uses to evaluate performance. For green tires, no compromise is required. Drivers can choose tires that have low rolling resistance with increased wet grip while maintaining abrasion resistance on a high level. A tire featuring the Silica/Silane-system can cut fuel consumption by up to 8 % and improve driving safety in wet conditions, an effect every driver notices. This increased fuel efficiency reduces the impact on the environment and the cost of running a car. Si 69® is still used in green tires to make them more sustainable and to help reducing the carbon footprint. 50 years after its development, its innovation is still recognized. And this further development continues today with Si 466® EXT, to enable a VOC-free production of tires.

With production sites in three continents and technical sites spread across the globe, Evonik stands alone in offering availability and reliability. Delivery is local and custom manufacturing needs can be met for silica and silanes products. Evonik’s partners can stay ahead of tomorrow’s challenges because the company doesn’t compromise on availability, reliability, or innovation.