How Si 363® in green tires is expanding the magic triangle

Silica/silane systems have long been standard in the production of cutting-edge, high-performance green tires. Tires manufactured with Si 363® lessen the burden on the environment and can reduce fuel consumption by up to eight percent compared to conventional tires. Evonik provides tire manufacturers with silica and silane from a single source – reliably and consistently.

Tires are what connect a car and the road, which is why their quality is a decisive safety factor. Good tires help drivers maintain a line through corners and ensure cars come to a standstill quickly and reliably when they hit the brakes – even in extreme weather conditions with snowy, wet or icy roads.

Alongside safety, sustainability is becoming ever more important. Modern tires must therefore fulfill a number of conditions: Rolling resistance should be as low as possible to reduce the vehicle’s fuel consumption – and thus CO2 emissions. At the same time, tires must display good adhesion properties in wet conditions in order to prevent the vehicle from sliding in corners or under heavy braking, while high abrasion resistance extends the life cycle of a tire.

The magic triangle

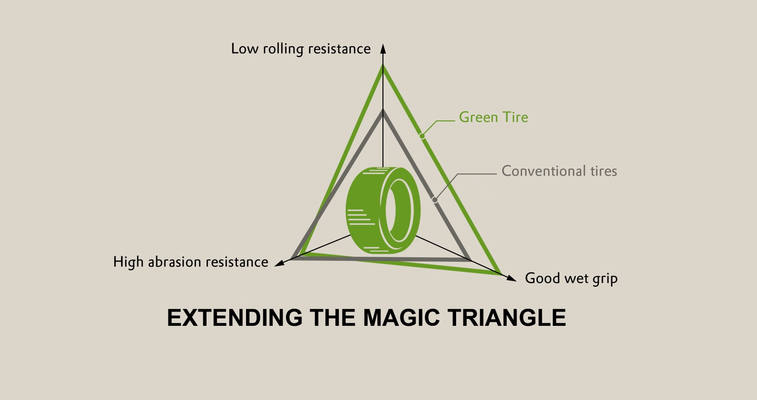

Rolling resistance, wet grip performance and abrasion resistance are the three points of the magic triangle for tire performance. The decisive factor here is the tread composition: It mainly comprises a mixture of rubber (polymer) that is optimized with reinforcing filler materials. Conventional tires use carbon black as a filler material. However, this system means it is not possible to improve any of the three corners of the triangle – or fundamental properties – without detracting from the other two aspects.

This changed almost overnight when “green tire” technology was introduced in the 1990s: The innovative silica/silane system from Evonik revolutionized tire production, as it significantly reduced rolling resistance and improved wet grip performance – all while the abrasion properties remained consistently good.

The special thing about this system is that precipitated silica is used in place of carbon black as the filler material in the rubber mixture. However, as polar silica is not very compatible with non-polar rubber, silanes were used here. Michael Kempf, head of the Tires and Mechanical Rubber Goods market segment at Evonik Silanes, explains: “Carbon black only has a physical bond with the polymer, but the bifunctional organosilanes chemically bind the tire silica to the polymer. This bond is significantly stronger, which means the tire can also withstand high loads.” In turn, this means more safety and lower costs for the driver, and the environmental burden is lessened.

“Si 363® expands the limits of what is possible”

Evonik has constantly improved the silica/silane system since introducing Si 69® in the early 1970s. In 2006/2007, the market launch of the silane Si 363® – known as VP Si 363® at the time – represented a huge jump forward in development: Compared to established silica/silane systems, Si 363® reduced the rolling resistance by a further 15 percent, while the reduction reached 35 percent when compared to the carbon black system. As a result, fuel consumption was reduced by up to eight percent when compared to the use of conventional tires, while braking distances were shortened considerably. “Si 363® expands the limits of what is possible – and blows open the magic triangle,” summarizes Kempf.

This benefits tire manufacturers that are focusing more on sustainability in line with the growing environmental awareness in society as a whole. Today, the silica/silane system used in modern quality tires represents an environmentally friendly alternative to the standard carbon black system. This is reflected in the EU tire label that was introduced in 2012 to make it easier to compare tires. The tire label was revised in 2021. Tires are placed into categories (A to G) according to their efficiency in the criteria of rolling resistance, wet braking properties and noise generation. Manufacturers use the silica/silane system to qualify their car tires for higher efficiency classes.

Bicycles with green tires

And cars are not the only beneficiaries of green tires – they are also used for bicycles. Evonik is also developing methods which will enable truck tires to be manufactured using the silica/silane system in the future.

Evonik is the only supplier that provides both key components for green tires – silica and silane – from a single source. At the same time, the company is the only Western supplier that manufactures rubber silanes at its own production sites on three continents. The company is therefore able to provide great supply security for tire manufacturers and offer technical support on site, thus helping them make their production even more sustainable. Car drivers and above all the environment benefit from this.